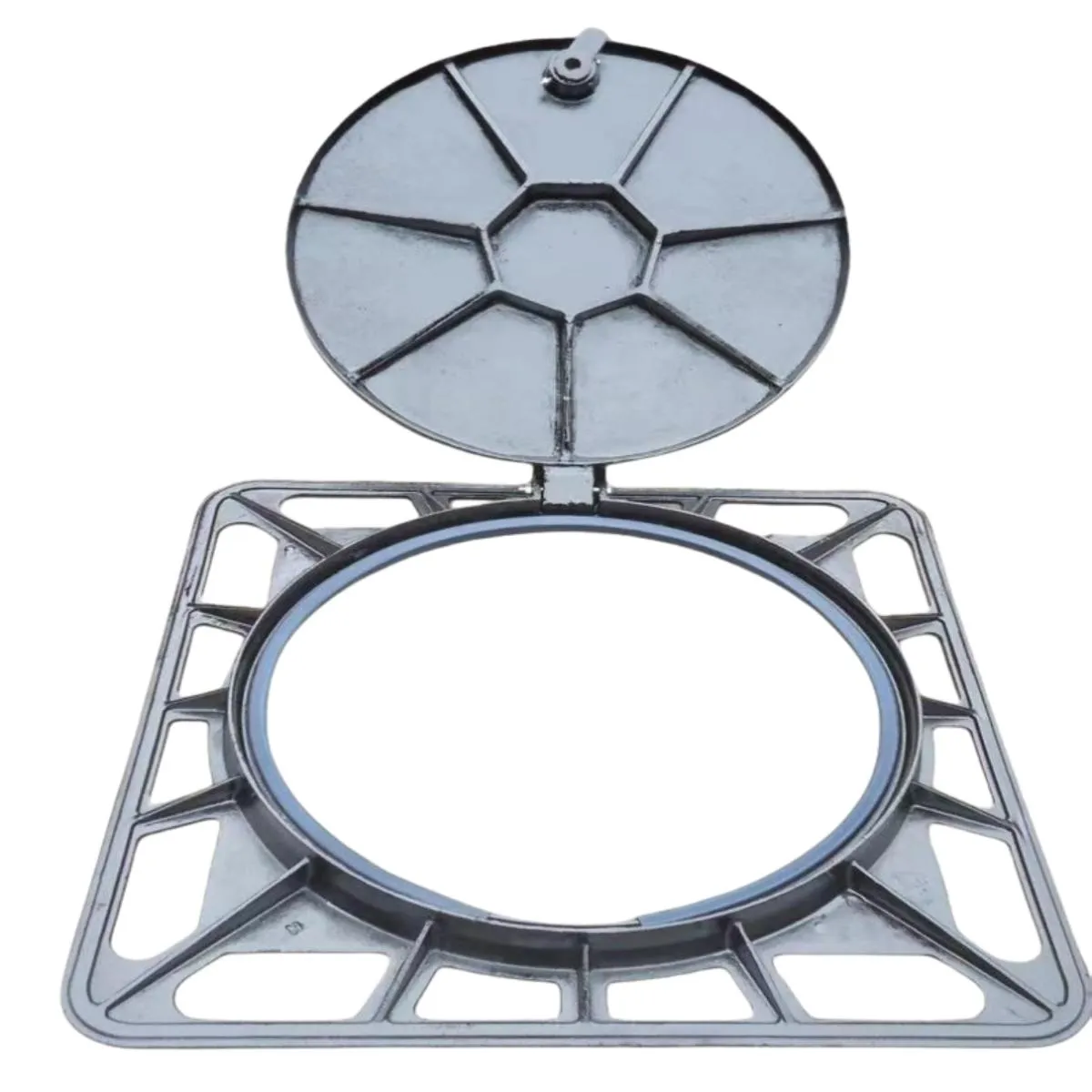

Regular maintenance of access covers and frames is essential for ensuring their functionality and safety. Municipalities are typically responsible for the inspection and upkeep of these structures, which may be governed by local regulations and standards. These regulations often dictate the materials used, load specifications, and design criteria to ensure that access covers can withstand the stresses of modern traffic and environmental conditions.

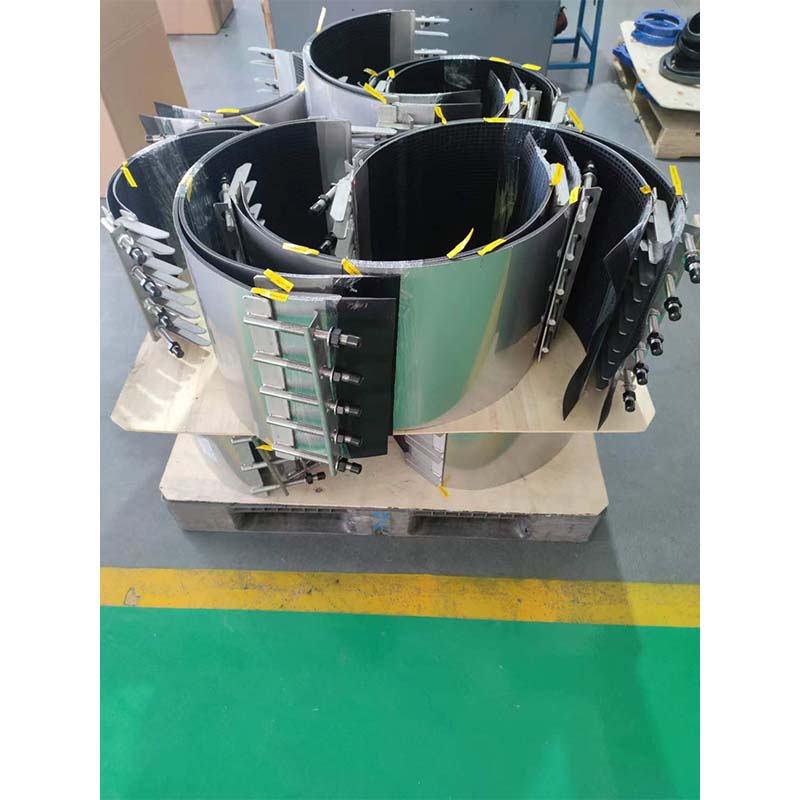

The primary materials used in saddle tee clamps include stainless steel, galvanized steel, and plastic. Stainless steel clamps are favored for their corrosion resistance, making them suitable for applications in harsh environments, such as oil and gas industries. Galvanized steel clamps provide an affordable and durable option while offering decent corrosion protection. On the other hand, plastic clamps are lightweight and non-corrosive, ideal for lightweight applications or where electrical insulation is necessary.

Cast iron is an alloy of iron with a carbon content greater than 2% and is characterized by its excellent casting properties. This allows for complex shapes and designs that can meet the diverse requirements of urban drainage systems. One primary advantage of cast iron gully grids is their strength and durability. Capable of withstanding heavy loads and significant wear and tear, cast iron grids are ideal for use on roads and in areas with high foot or vehicle traffic.

Applications of Automatic Bollards

Understanding Recessed Covers and Frames A Comprehensive Overview

Moreover, in an era where urban spaces are becoming multicentric and multifunctional, locking bollards play a vital role in promoting smart city initiatives. With the integration of technology, bollards can be equipped with sensors and connectivity features that allow them to communicate with traffic management systems. This could enable dynamic adjustments based on traffic flow, paving the way for more efficient urban mobility and enhanced public safety.

5. Eco-Friendly Options As environmental concerns grow, many manufacturers are now producing flexible bollards from recycled materials. This not only helps in reducing waste but also promotes sustainable practices within urban infrastructure.

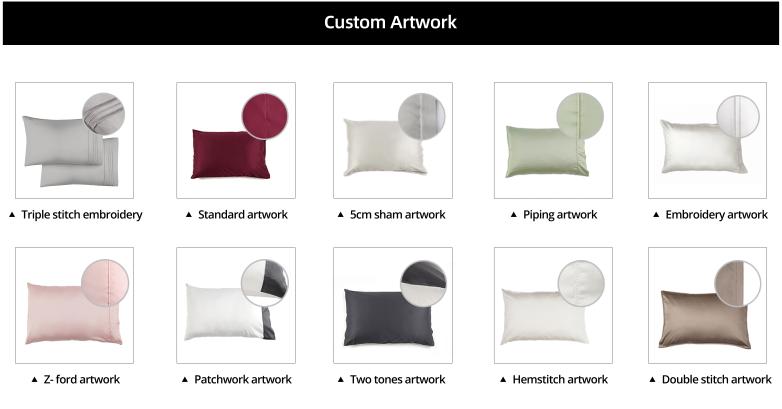

They come in a variety of sizes, colors, and styles, making them suitable for a wide range of uses They come in a variety of sizes, colors, and styles, making them suitable for a wide range of uses

They come in a variety of sizes, colors, and styles, making them suitable for a wide range of uses They come in a variety of sizes, colors, and styles, making them suitable for a wide range of uses The 12% thickness allows for a balance between durability and malleability, making them suitable for welding, cutting, and bending operations The 12% thickness allows for a balance between durability and malleability, making them suitable for welding, cutting, and bending operations

The 12% thickness allows for a balance between durability and malleability, making them suitable for welding, cutting, and bending operations The 12% thickness allows for a balance between durability and malleability, making them suitable for welding, cutting, and bending operations